Well, kind like a jokes when a chemical engineers doesn't know how to choose the right pump for fluid transfer in their plant design or for a fresh graduate which just "born" to the jungle. Then this article might help you when dealing with this matter.

Today discussion was focused on choosing pump. When choosing a pump, it is important to match a pump’s capabilities with system requirements and the characteristics of the liquid being processed. These factors include the inlet conditions, required flow-rate, differential pressure and liquid characteristics. Generally, the quality of the liquid should remain unchanged after passage through a pump. Therefore, material compatibility, viscosity, shear sensitivity and the presence of particulate matter in a liquid are important considerations in pump selection. Most engineering applications employ either centrifugal or positive displacement (PD) pumps for fluid handling. These pumps function in very different ways, so pump selection should be based on the unique conditions of a process.

- Centrifugal Pumps

The most widely used pump in the chemical process industries for liquid transfer is the centrifugal pump. Available in a wide range of sizes and capacities, these pumps are suitable for a wide range of applications. Advantages of the centrifugal style include: simplicity, low initial cost, uniform flow, small footprint, low maintenance expense and quiet operation. - Positive displacement pumps

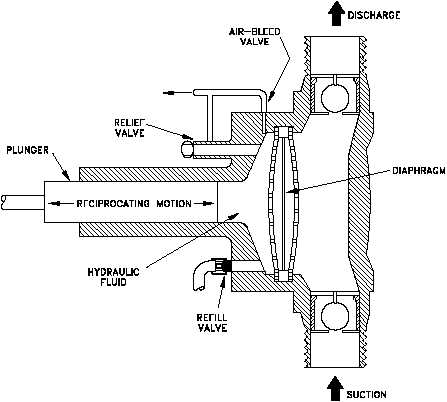

Though engineers may be first inclined to install centrifugal pumps, many applications dictate the need for PD pumps. Because of their mechanical design and ability to create flow from a pressure input, PD pumps provide a high efficiency under most conditions, thus reducing energy use and operation costs. - Centrifugal VS Positive Displacement ??

These two main pump styles respond very differently to various operating conditions, so it is essential to evaluate the requirements of a process prior to choosing an appropriate pump. Table 1 illustrates the mechanical differences between these pumps, as well as the effects of pressure, viscosity and inlet conditions on flowrate and pump efficiency.

Range of operation Pump styles range far beyond simply PD and centrifugal pumps. PD pumps encompass many specific styles, including a variety of reciprocating, rotary and blow-cover pumps. Likewise, centrifugal pumps encompass radial, mixed, and axial flow styles, which all belong to a greater category of kinetic pumps. A simple way to narrow down pump styles is to determine the required capacity that your pump must handle. Based upon a required capacity in gal/min. and a pressure in lbf/in.2, the pump coverage chart below can help engineers focus their selection to a just a few pump styles.

- Casting connection:

Volute casing efficiently converts velocity energy impacted to the liquid from the impeller into pressure energy. A casing with guide vanes reduce loses and improve efficiency over a wide range of capacities, and are best for multistage highhead pumps - Impeller details:

Closed-type impellers are most efficient. Opentype impellers are best for viscous liquids, liquids containing solid matter, and general purposes - Sealings:

Rotating shafts must have proper sealing methods to prevent leakage without affecting process efficiency negatively. Seals can be grouped into the categories of noncontacting seals and mechanical face seals. Noncontacting seals are often used for gas service in high-speed rotating equipment. Mechanical face seals provide excellent sealing for high leakage protection - Bearings:

Factors to take into consideration while choosing a bearing type include shaft-speed range, maximum tolerable shaft misalignment, critical-speed analysis, loading of compressor impellers, and more. Bearing styles include: cylindrical bore; cylindrical bore with dammed groove; lemon bore; three lobe; offset halves; tilting pad; plain washer; and taper land. - Materials:

Pump material is often stainless steel. Material should be chosen to reduce costs and maintain personnel safety while avoiding materials that will react with the process liquid to create corrosion, erosion or liquid contamination

- “Perry’s Chemical Engineers’ Handbook,” 7th ed. New York: McGraw-Hill, 1997.

- Petersen, J. and Jacoby, Rodger. Selecting a Positive Displacement Pump, Chem. Eng. August 2007, pp. 42–46.